Processes for metal recovery reach from fairly simple to highly complex – depending on the value and content of the metal in the slag on one side, and on the desired application for the residual slag on the other side. Process types might be grouped into

- Simple crushing and screening processes for coarse metal recovery

- for low value metals or low metal contents

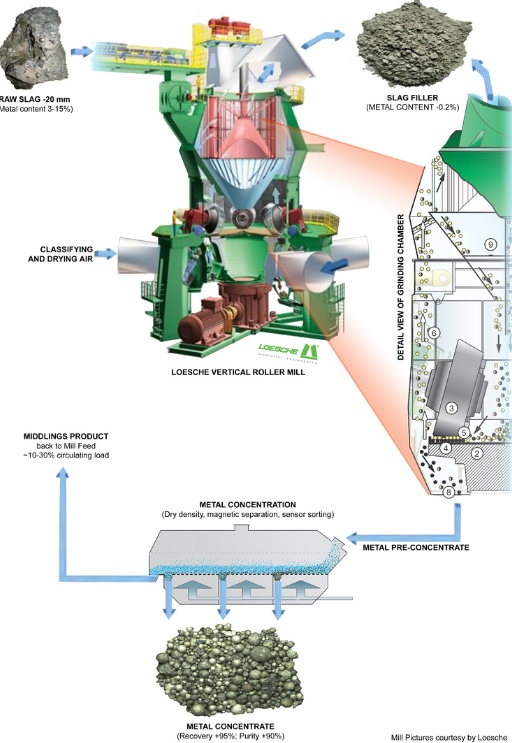

- Fine grinding processes for maximum metal recovery

- for high value metals or high metal contents

- wet or dry

- get out nearly everything and have a uniform slag powder or slime as by-product

- More complex pre-concentration processes for reducing the production of fines and grinding energy consumption

- For brittle metals (like Ferrochromium) or if residual slag is marketed as aggregate

- by sensor separation, jigging and fine gravity separation, magnetic separation and similar, metal recovery from pre-concentrates OR only free metal recovery

CALA has developed and optimised processes for all of those versions, wet or dry. We find out which process suits you best.