We have served some of the biggest mill service companies as well as steel mills and local slag handling companies with services like

- Slag analyses for metal contents, chemical and mineralogical compositions, marketability

- Metal Recovery Plant concepts

- Mineral Product valorization concepts

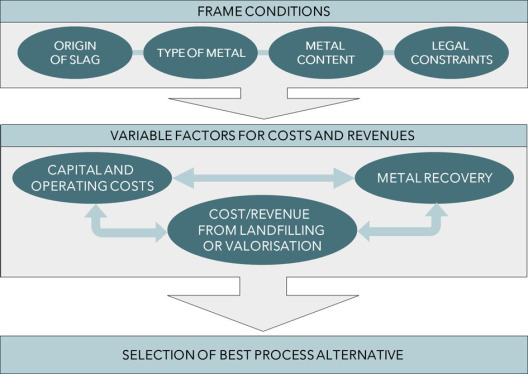

Our specialty is to maximize metal recovery without losing track of the valorization of the residual slag, since it can be a high-value product and the cost of disposal generally increases.

Whether it is slag from ferroalloy (FeCr, FeMn, and others), stainless steel or carbon steel mills (BOF / LD, EAF and ladle furnace slags) on the one hand, or slags from base metal smelting (copper slags, lead slags, ...) on the other hand, we will find the optimum solution for each slag type and each market.

The motivation for slag processing in most cases is the recovery of metal, but the key to success is to find a maximum value application for the mineral part of the slag.